- Address: Limburg/Germany

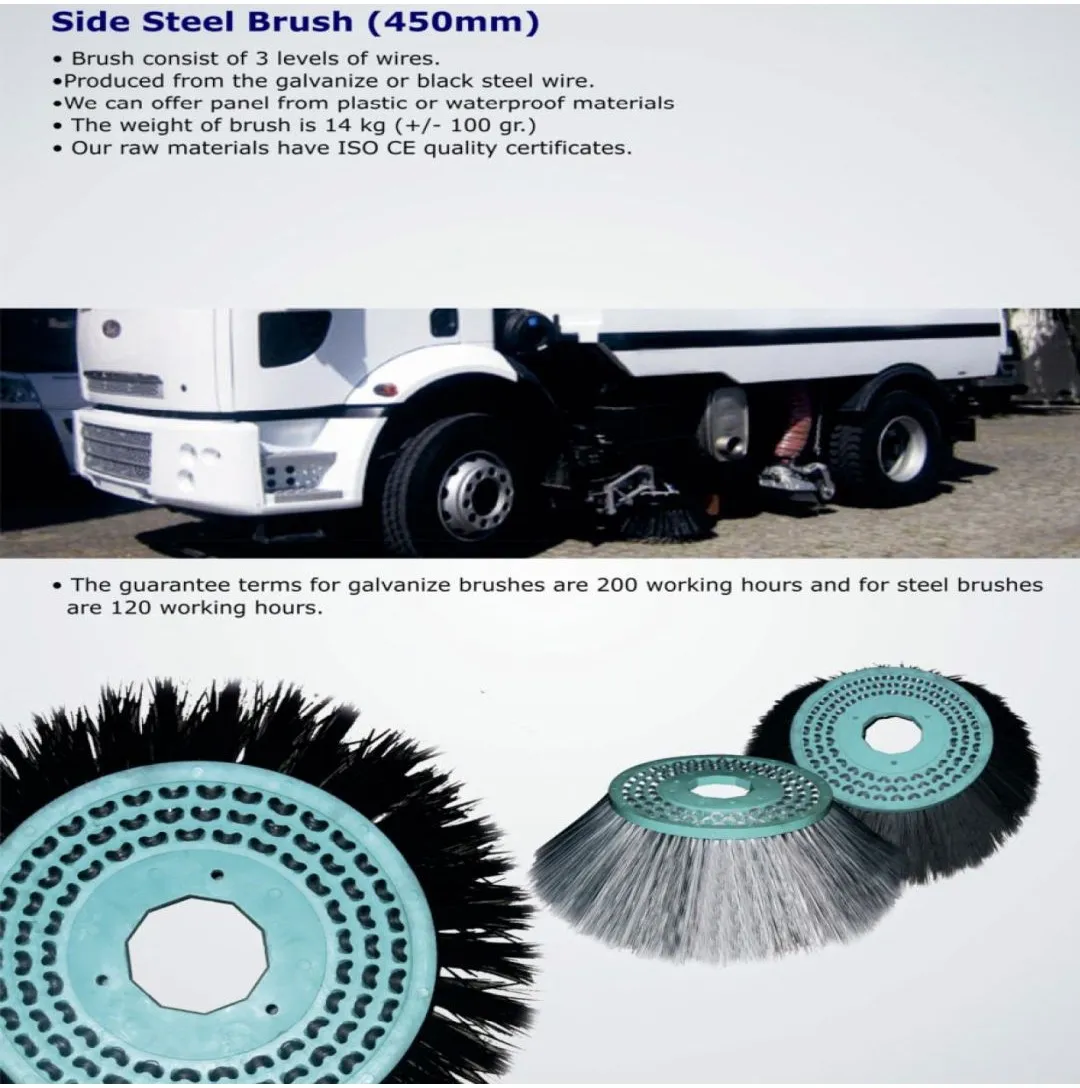

This is the 450 mm side brush for road sweeping vehicles.

Get Information from WhatsAppThis is the 450 mm side brush for road sweeping vehicles. It is manufactured from steel wire. The base plate used is produced by us from unbreakable, durable plastic. It is manufactured in compliance with international standards. All materials used are fully compatible and guaranteed by our company. Upon request, we provide our customers with ISO, CE, and analysis reports. All of our products are 100% domestically produced. The galvanized wire model comes with a 200-hour lifespan guarantee, while the black steel wire model is guaranteed for 120 hours.

Road sweeping brushes are brushes specially produced for the specific area in which they are used.

Depending on certain features, road cleaning and sweeping brushes can also be custom-made upon request and are used for cleaning many different areas.

The areas where sweeping brushes are commonly used include roads, parks, sidewalks, gardens, warehouses, and similar large spaces.

It is possible to use road sweeping brushes in these areas.

Sweeping brushes are used to provide both effective and efficient cleaning in the areas where they are used.

By using different types of brushes, cleaning can be carried out more easily.

Cleaning streets and similar large areas requires a great deal of effort.

By using road sweeping vehicles, more surface area can be cleaned in a shorter period of time.

In road sweeping brushes, product features are highly important.

A person who wants to buy a sweeping brush generally looks at the inner diameter and outer diameter of the base.

The base length is also important in terms of the characteristics of the bristles on the brush.

Depending on the features of the brush, it is possible to adjust certain properties of the bristles.

So, what is a road sweeping brush?

What are the types of road sweeping brushes?

According to which factors are road sweeping brushes selected?

How much do sweeping brush prices cost?

Road sweeping brushes are brushes attached to machines used for cleaning large areas.

It is possible to produce road sweeping brushes based on the application area and specific requests.

Therefore, it is easy to find a road sweeping brush that suits the desired area.

Road sweeping brushes can be obtained easily and quickly.

Road sweeping brushes are used to clean public areas such as roads, parks, and gardens, as well as weedy areas, warehouses, and similar large spaces, including sidewalks.

These brushes are highly important for environmental cleaning operations and are available in various types for different road cleaning vehicles.

As a result, the desired brushes can be found easily.

Road sweeping brushes are mounted on vehicles responsible for cleaning certain areas.

Depending on the area being cleaned, the type of brush used may vary.

While a different brush is used for roads, parks, and gardens, another type is preferred for warehouses and similar spaces.

The shape of the sweeping brushes also changes according to their intended area of use.

There are various types of road sweeping brushes that perform their tasks effectively and efficiently.

These brush types can be obtained quickly and easily.

Cleaning and road sweeping brushes are designed to provide efficient and effective cleaning in the areas where they are used.

The types of road sweeping brushes are specially produced for different areas.

There are specific road sweeping brushes that need to be used in certain areas.

The shapes of the brushes also vary depending on their usage areas.

It is possible to encounter brushes in various shapes.

Sweeping brushes can be produced in cylindrical, panel, or circular forms.

These commonly used shapes are designed to provide more effective and efficient cleaning in the areas where they are used.

Specially manufactured road sweeping brushes can also be custom-made for the specific road sweeping vehicle being used.

Road sweeping brushes can also be in panel form.

Panel-shaped parts are a type of sweeping brush used for cleaning flat and easy-to-clean surfaces.

The type of road brush that enters certain areas to perform the cleaning task is the cylindrical road brush.

Silicone road brushes are frequently preferred due to their unique structural properties.

Central road sweeping brushes are a type of brush that takes on the task of cleaning the spaces in between areas.

In addition to the central road sweeping brush, the side steel road sweeping brush is also preferred.

The frequently used central road sweeping brushes can be produced with different cleaning tips, making them a more efficient cleaning tool.

450 mm Side Steel Brush Prices from the Manufacturer

Many companies around the world manufacture road sweeping vehicles.

In the important market of the road cleaning sector, our country also has well-known brands, and these brands are used both for cleaning roads in Turkey and are exported to many countries.

Brands such as Erdemli, Çeksan, Katmerciler, Koluman, Kademe, and Hamarat are among the prominent domestic names.

In addition, Hako, Scarab, Ravo, Schörling, Johnson, Dulevo, Azura, Karcher, Butcher, Schmidt, Swingo, Clingo, Nilfisk, Tennant, Tenax, Tisan, Bobcat, and Green Machine are globally recognized brands.

These road sweeping machines are used in many countries around the world.

Road sweeping brushes are chosen by considering various important factors.

Using sweeping brushes in unsuitable areas may result in ineffective cleaning of the intended space.

Therefore, it is essential to pay attention to certain elements when selecting a brush, and to choose the appropriate brush type based on the characteristics of the area to be cleaned.

Road sweeping brushes must first be selected according to the characteristics of the area where they will be used.

After finding the brush suitable for the environment, it should be checked whether the road sweeping brush is compatible with the vehicle.

Once it is confirmed that the brush is suitable for both the environment and the vehicle, the cleaning process can be started easily.

The features of road sweeping brushes can be customized.

There are sweeping brushes specially made for many vehicles and environments.

The inner and outer diameters of the brush base have specific measurements.

Therefore, the bristle tufting pattern and bristle density are determined based on the characteristics of the brush base.

The bristle thickness of road sweeping brushes also falls within a certain range.

The features of bristle thickness and bristle length are similar to each other.

Once the desired brush type is determined, you can easily identify the type of road sweeping brush you need by examining the bristle tufting pattern and bristle density.

You can also use product codes to simplify and speed up your purchasing process.

Road sweeping brush prices vary depending on several different factors.

Therefore, it is not possible to provide a fixed price for road sweeping brushes.

The prices of road sweeping brushes increase or decrease based on certain features the brushes possess.

By evaluating these features, it is possible to make an estimate regarding the brush’s price.

In general, the prices of 450 mm side steel brushes or front brushes are more affordable compared to central brushes.

The central brushes of sweeping vehicles like Erdemli or Dulevo tend to have higher prices.

In our country, steel prices are more affordable than in other countries.

For this reason, the most reasonably priced products in local production are usually side steel brushes.

The most important factor affecting brush prices is the size, in other words, the weight of the brush.

When calculating the cost of a brush, the amount of material used and the labor cost are determining factors.

Another factor that causes an increase or decrease in road sweeping brush prices is the bristle tufting pattern and bristle density used in the brush.

When the tufting style and density change, the price of the sweeping brush also changes.

For this reason, those who want to purchase a sweeping brush should consider the price variations caused by different tufting styles and densities.

Another factor affecting the price of road brushes is their type.

When brush types change, their features also change.

These changes in features cause the prices of sweeping brushes to increase or decrease.

By knowing the factors that influence road brush pricing, you can more easily make the right brush selection.

450 mm Side Steel Brush prices from the manufacturer

For those who want to buy road brushes, it is very important to be informed about sweeping brush prices.

Once you understand which features influence price changes, it becomes easier to find and obtain a reasonably priced road sweeping brush.

Especially in the last two years, due to the pandemic that affected the world, raw material prices have significantly increased, and this upward trend still continues.

Therefore, brush costs and prices have risen considerably in the last two years.

However, despite this, domestic production in our country is quite reasonable in terms of both quality and price.

High-quality products are sold at very reasonable prices in our country.

You can contact us through the communication channels on our official OSB Bazaar website to get more information about road sweeping brush prices.

You can easily and quickly find answers to your questions about Erdemli central brushes and many other types of road sweeping brushes.

Road sweeping brushes play a crucial role in maintaining the cleanliness of our cities and ensuring a healthy environment.

Due to friction, these brushes wear out over time and must be replaced at regular intervals, making them an essential need today.

When it comes to the production of road sweeping brushes, our country is one of the leading nations.

In particular, when the price/quality balance is taken into account, manufacturers from our country attract the attention of international companies.

Foreign companies that own vehicles such as Hako, Scarab, Schmidt, Bucher, Ravo, Johnson, Dulevo, Azura, Karcher, and Nilfisk often face very high costs when purchasing brushes either from their own factories or from large manufacturers such as Fayat and Isal.

However, the prices offered by our company are much more affordable compared to these factories.

In fact, we provide the same or even better quality brushes at significantly better prices.

Since these vehicle manufacturers are located in Europe, labor and other production costs are much higher compared to those in our country.

Moreover, our craftsmanship is far superior to that of these factories.

Our customers consistently express their satisfaction with the quality of our products.

Due to the reasons mentioned above, there has been a significant increase in the export of road sweeping brushes in recent years.

In many countries around the world, brushes produced in Turkey are safely cleaning cities.

In this way, we contribute significantly to both our country’s exports and economy, as well as to the global promotion of our nation.

As OSB Bazaar, with our vast experience and reliability, our road sweeping brush sales continue worldwide.

You can reach us through the contact channels available on our official website to get more information about sweeping brush prices.

You can easily and quickly get answers to your questions about Erdemli central brushes, Dulevo main brushes, Johnston side brushes, 450 mm side steel brushes, and many other types of road sweeping brushes and obtain these brushes at the most affordable prices.

Road sweeping brushes can be manufactured from different materials depending on the area of use, usage method, road conditions, and the amount of dirt present.

In general, the brushes used in road sweeping vehicles are produced in three types:

Plastic (Polypropylene)

Steel

Plastic (PP) + Steel mixture

Each of these materials has certain standards.

In order for polypropylene to provide efficient and long-lasting performance, it must have a specific fluidity.

The fluidity of polypropylene should meet the 3–5 MFI standard.

Steel brushes are produced using crimped steel wire, and their quality is determined by the carbon content of the material.

Depending on usage and preference, brushes can also be made from nylon, polyester, and abrasive materials.

We do manufacture nylon brushes. However, in Turkey, polyester is not typically used in brush manufacturing.

Brushes made from nylon and polyester are more expensive than those made from polypropylene due to their higher production costs.

Abrasive material is used for extremely tough surfaces and acts similarly to sandpaper.

It is not suitable for general use and is mainly used in areas where cleaning is nearly impossible.

Because abrasive materials are more expensive, abrasive brushes are also priced higher than other types.

Side brushes used in vehicles such as Johnston, Bucher, Schörling, and Scarab are typically made from steel because steel brushes offer very high durability.

Common examples include the Johnston 450 mm Side Steel Brush, Scarab Side Steel Brush, and 400 mm Side Steel Brush.

These side brushes are rarely made only from plastic; however, they can be produced as plastic + steel combinations upon request.

Front brushes used in vehicles like Hako, Schmidt, Swingo, Clingo, and Azura are generally made from plastic.

For instance, front brushes of Hako or Schmidt Swingo 200 vehicles are usually manufactured from plastic (polypropylene), but they can also be made as plastic + steel mixtures, or even from steel, depending on customer demand.

Central brushes (also called main brushes) used in Erdemli, Dulevo, Schörling, and Scarab road sweeping vehicles are manufactured from plastic (polypropylene).

They can also be made as plastic + steel mixtures upon request, but these brushes are never produced entirely from steel.

For example, Erdemli Central Brushes and Dulevo Main Brushes are entirely made from plastic materials.

As OSB Bazaar, with our vast experience and reliability, we can help you determine which type of brush and what material is best suited for your needs.

You can contact us through the communication channels listed on our official website to get more information about sweeping brush prices.

Front brushes are produced in a wide variety of sizes.

Common front brush sizes include:

30x390 mm, 130x400 mm, 180x600 mm, 180x800 mm, 255x600 mm, 255x800 mm.

Inner and outer diameters can also be adjusted depending on usage and preference.

Common inner diameters include:

72 mm, 76 mm, 110 mm, 114 mm, 128 mm, 130 mm, 160 mm, 162 mm, 178 mm, 180 mm, 203 mm, 220 mm, 254 mm, 255 mm

Outer diameters generally start at 300 mm and go up to 900 mm.

Bristle thickness can also be customized according to preference.

Side brushes are typically produced in sizes such as:

300 mm side steel brush, 400 mm side steel brush, and 450 mm side steel brush.

Custom production in different sizes is also available upon request.

Commonly used side brush dimensions include:

320 x 80 x 500 mm, 320 x 80 x 600 mm, 350 x 80 x 600 mm,

400 x 100 x 700 mm, 420 x 200 x 720 mm, 450 x 200 x 750 mm,

490 x 320 x 800 mm, 490 x 840 mm, 520 x 250 x 850 mm,

520 x 250 x 880 mm, 770 x 1100 mm

Central brushes are also produced in a variety of sizes.

Typical sizes include:

40x40x1300 mm, 45x45x1500 mm, 50x50x1300 mm

Custom dimensions can be produced depending on usage and preferences.

Additional commonly used central brush sizes include:

46 x 350 x 750 mm, 46 x 400 x 750 mm, 47 x 380 x 650 mm,

51 x 400 x 1000 mm, 51 x 510 x 750 mm, 51 x 550 x 750 mm,

51 x 550 x 800 mm, 51 x 600 x 1000 mm, 51 x 600 x 1200 mm,

51 x 600 x 800 mm, 51 x 550 x 1000 mm, 51 x 800 x 1150 mm

Since road sweeping brushes used in sweeping vehicles come into direct contact with the ground, they are subject to friction during operation.

For this reason, they must be replaced after a certain period of use and at regular intervals.

In short, every brush has a service life.

Brushes that have reached the end of their lifespan lose their effectiveness and can no longer perform proper cleaning.

There are many factors that determine the lifespan of road sweeping brushes. These can be examined under the following headings:

1– According to the Area of Use:

Road sweeping brushes are used on different road surfaces depending on the layout of the cities.

Although brushes are generally designed for use on asphalt, they may also be used on concrete or soil surfaces.

However, if brushes produced for asphalt surfaces are used on soil, their lifespan will be shorter.

Therefore, the surface where the brush will be used should be taken into account when selecting a brush, and special production should be requested for special surfaces.

For example, a brush intended for use on asphalt should not be used on soil; the manufacturer should be informed, and a more suitable brush should be produced.

2– Dirt Level on the Roads:

In some regions, the amount of dirt can be higher than usual.

There may be waste such as mud or leaves that must be cleaned.

In such cases, the manufacturer should be informed, and the most suitable brush should be provided.

As mentioned, using standard brushes in areas with different types of dirt may result in ineffective cleaning and shorter brush life.

For instance, a standard Hako front brush that performs well on asphalt may lose its function on muddy roads.

Therefore, the bristle thickness of a Hako front brush intended for muddy roads should be adjusted accordingly.

3– Bristle Thickness:

The bristle thickness must be designed based on the area of use and the ground type to ensure both longer lifespan and effective cleaning.

For example, a standard Bucher central brush that performs well on asphalt may have reduced efficiency and lifespan on muddy surfaces.

Thus, the effectiveness and performance of a Bucher central brush used in different conditions can be improved by increasing the bristle thickness.

4– Quality of the Materials Used:

The most important factor determining brush lifespan is undoubtedly the quality of the brush.

Brushes produced by different manufacturers in different quality levels will, of course, not have the same lifespan.

As previously mentioned, the quality of the materials used in brushes is crucial.

Manufacturers who compromise on quality to reduce costs inevitably produce brushes with shorter service lives.

5– Environmental Factors:

Environmental conditions vary from country to country.

For instance, in countries like Russia, where temperatures are extremely low, there are no significant issues with brush durability.

However, in countries like Qatar, located in the Southern Hemisphere, where temperatures are excessively high, brushes may deteriorate due to heat.

In such regions, temperature-resistant brushes should be manufactured accordingly.

Additionally, rain, heat, dust, impact, vehicle structure, installation, maintenance workmanship, and sun exposure are all environmental factors that affect the lifespan of the brush.

Brushes made of plastic, such as the Hako front brush, Erdemli central brush, and Azura front brush, should definitely not be stored in sunny environments.

They must be installed by expert personnel and used according to the specified conditions.

Steel brushes such as the Johnston side steel brush, Scarab side steel brush, and the 400 mm side steel brush should not be stored in humid environments.

They should also be installed by professional personnel and used in accordance with usage guidelines.

As OSBBazaar, with our vast experience and confidence, you can contact us through the communication channels on our official website to learn more about sweeping brush prices, which brush is most suitable for you, and under what conditions each brush should be used.

Road sweeping brushes are used in sweeping vehicles such as Erdemli, Hako, Scarab, Ravo, Schörling, Johnson, Dulevo, Azura, Karcher, Butcher, Schmidt, Swingo, Clingo, Nilfisk, Tennant, Tenax, and Tisan, Bobcat.

They are used on asphalt, concrete, and soil surfaces, and in smaller models of Karcher sweepers, they are also used for cleaning places like workplaces and hotels.

In general, road sweeping brushes are used in roads, parks, sidewalks, gardens, warehouses, and similar locations.

You can safely obtain the desired brand and model of road sweeping brushes by contacting us through our official website: www.osbbazaar.com.

Kein Tabelleninhalt gefunden.